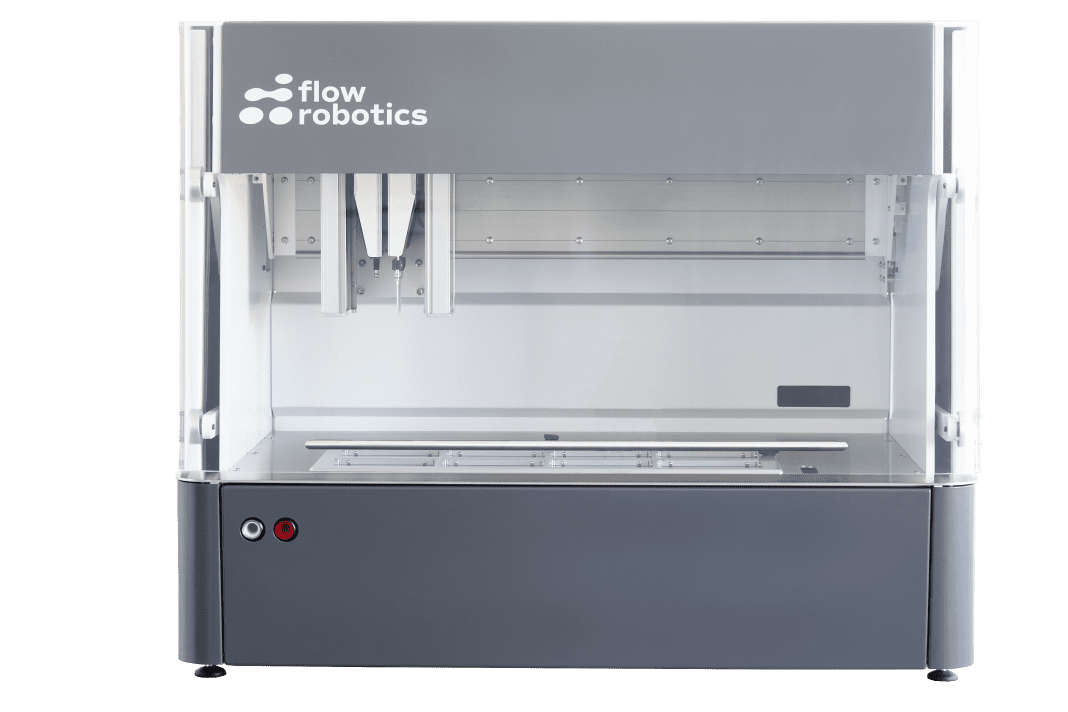

Flow Robotics, is a Denmark-based leading designer and producer of robots for automated liquid handling and the creator of the flowbot® ONE.

Today the company announced today that it has established its North American Subsidiary, Flow Robotics, Inc., with operations in Princeton, NJ. The company’s first product, the flowbot® ONE, is designed to transform how liquid handling responsibilities are performed in the laboratory by automating manual pipetting tasks. The robot will be showcased for the first time in the U.S. at the SLAS 2021 Americas Sample Management Hybrid Symposium September 9-10 in La Jolla, CA.

The flowbot® ONE debuts at a pivotal moment for the laboratory industry plagued for years with high workloads, burnout, and physically challenging conditions recently exacerbated by the COVID-19 outbreak. The pandemic brought an increased necessity for collecting and preparing virus samples quickly, safely, and accurately.

“We are excited to expand our operations in North America,” said Annika Isaksson, CEO of Flow Robotics. “Our technology is setting a global precedent in life sciences, healthcare and academia, delivering faster and more accurate lab results. The flowbot® ONE helps labs achieve a more sustainable setup by taking over many of the repetitive and burdensome manual pipetting tasks. In turn, lab personnel can engage in other more valuable activities. flowbot® ONE also reduces human error and work-related injuries, resulting in an overall increase in lab productivity, where humans and robots can work in parallel.”

Flow Robotics estimates that about half of medical lab technicians carry out the same arm movements for at least a quarter of their working day. Manual pipetting is a large part of liquid handling in any laboratory, and it brings hours of repetitive work in fixed positions. This can result in physical strain to the shoulders, arms and hands. The American Society for Clinical Pathology found that 85 percent of laboratory professionals suffer from burnout; 36 percent struggle with inadequate staffing; and 32 percent face a heavy workload and pressure to complete all testing on time.

Flexible Ease of Use and Adaptability to Perform Multiple Tasks

Unlike other automated liquid handling robots, flowbot® ONE does not require advanced programming skills so just about anyone can set up a procedure. The robot also has the ability to integrate to devices positioned on the deck or external to the system. It also supports the import and export of data.

In addition, flowbot® ONE can play a role in many different pipetting applications and tasks in the lab. This includes, PCR and qPCR, normalization, sample aliquoting, microplate filing, next generation sequencing (NGS), ELISA sample preparation, assay development, screening, reformatting, cherry picking, transferring, serial dilution, plate replication and reformatting.

“We continue to see the need for more flexibility in robotics automation in clinical and research labs across the world,” said Craig Cardella, Vice President and General Manager for Flow Robotics’ new North American division. “I am excited to bring this capability to labs in North America with flowbot® ONE to help increase productivity and change the way they do business.”

“The flowbot® ONE’s intuitive and flexible system is in use at some of the largest hospitals, biotech and pharmaceutical companies and academic research labs across the world, and we look forward to seeing the same success in North America,” continued Isaksson.

Plays Integral Role in Fight Against COVID-19

Since May 2020, the flowbot® ONE has played an integral role in the fight against COVID-19 by speeding up the analysis of COVID-19 tests while keeping laboratory assistants safe. Today, more than 600,000 COVID-19 tests are being prepared each month on a flowbot® ONE in Europe, where the robots pipette the live virus, handling several samples simultaneously, all working from a predefined pipetting pattern.

Significant Increases in Lab Productivity

Unilabs, one of the largest diagnostic providers in Europe, uses five flowbot™ ONE robots to help screen sclerosis patients for viruses. The flowbot™ ONE has helped to increase lab productivity by 40 percent and reduced the time patients need to wait for results by 30 percent.

Nordic Bioscience, a biomarker powerhouse that develops novel biomarkers and performs clinical trials, automated their clinical lab equipment with the flowbot® ONE to help optimize the work process and reduce pipetting for biomarker measurements. Hands-on lab time was reduced from 2 hours and 15 minutes to 20 minutes when running up to 8 biomarkers simultaneously in the lab.