Mini motors provide a cost-effective, maintenance-free solution for the medication dispenser, which can be installed in systems designed for home use notes Portescap.

Automated medication dispensers for use by the patient have become more widespread with an increasing population and a demand for easier and more controlled self-administration of medication.

Designed to be used without medical supervision, automated medication dispensers significantly reduce the potential of patients taking the wrong medicine at the wrong time or failing to administer. The dispensers also give patients greater control over their own medical care. The key demands on the system include accuracy and reliability of alerting the patient and dispensing, as well as ease of use for patients who are often elderly. Considering the public user base, automated medication dispensers also have to be low-cost and must feature a robust construction.

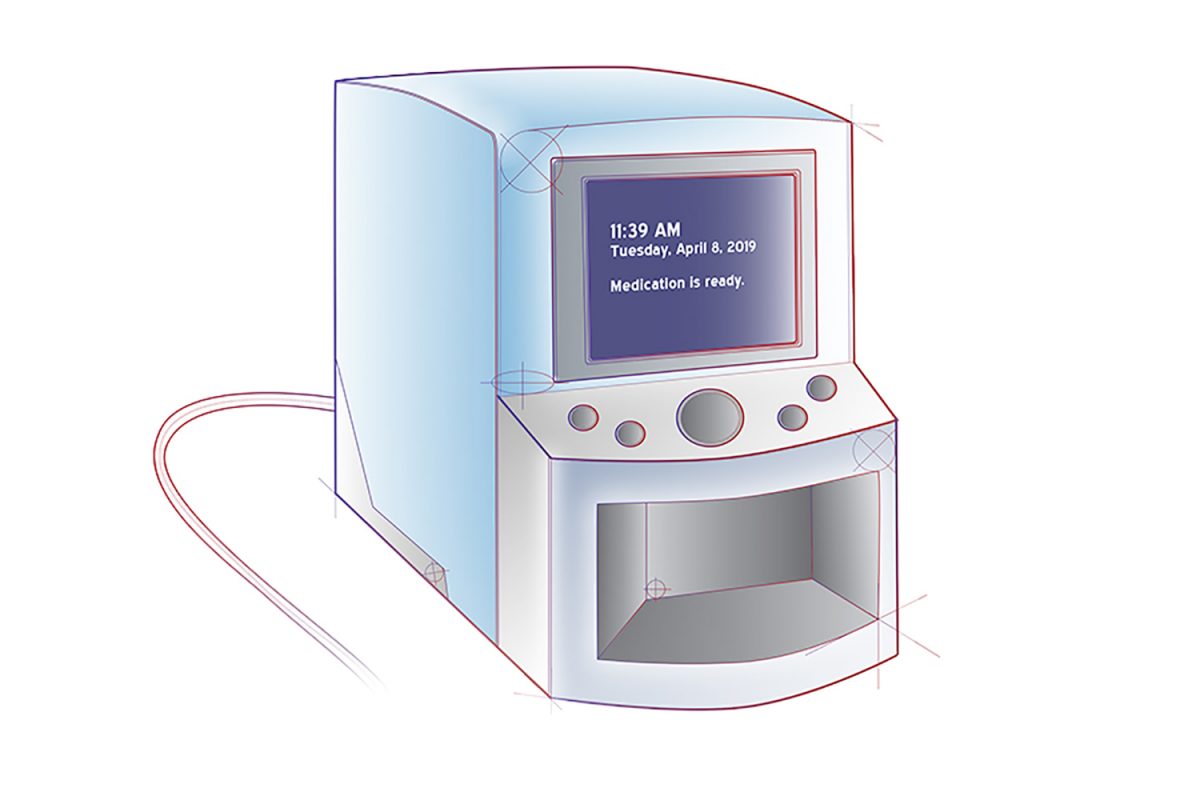

A North American medical device innovator required a motor solution for an automated medication dispenser, which would provide accuracy and reliability of control at a competitive price. The dispenser includes an audible alarm and LED visual indicator, which alerts the patient when to take their medication. It presents user information via a clear, easy-to-read screen and is simply controlled by large buttons, connected to a micro-motion system that actuates the carousel holding the multiple pill containers. Demands on the mini motor’s motion control include repeatable accuracy with higher torque at low speed. Portescap was selected as the project partner because of the comprehensive engineering consultancy provided in combination with its experience in miniature motion solutions.

Initially, the customer had considered using a brush DC motor, however, Portescap’s engineers advised on the advantages of a stepper motor, which would provide repeatable, accurate motion at a more competitive price. As a result, the customer specified a Portescap 42L048D can stack mini-stepper motor. The design of Portescap’s can stack motors ensures positional accuracy and the construction features a simple, reduced component design for increased reliability.

Usually two-phase, the can stack motors comprise two motor halves having two stator cups, each with poles formed around a winding. The rotor has the same number of pole pairs as the stator. Meanwhile, the poles on each stator cup are designed half a pole pitch apart. Two coils create four discrete positions per pole pitch and the 42L048D, with 12-pole pairs in each stator, has 48 steps per revolution or 7.5 degrees per step. This creates a high level of control accuracy and while open loop, means that no encoder is necessary, reducing cost and footprint.

Motor speed and length of rotation are directly related to input pulse frequency and any error is non-cumulative, which enhances repeatability of control. To ensure high torque at low speed, necessary for precision control of the dispenser’s carousel which holds the medication trays, the 42L048D features a large rotor and neodymium magnets, providing up to 18.5 oz-in (131 mNm) of holding torque.

The simplicity of design means efficient operation with a low energy requirement. The 42L048D also ensures quiet operation, ideal for home residential use or settings which demand low audible noise for patient care.

The low count of moving parts combined with a robust design means that the mini motor is maintenance-free with no replacement of bushes required. This is an essential attribute for automated medicine dispensers with a key role in residential settings. The mini motors also feature a sintered bronze bearing design for increased resilience, enhanced with long life lubrication.

The mini motor can be digitally controlled with simple installation and interfacing with a microprocessing drive. The 42L048D can be paired with Portescap’s EDM-453 micro-stepping drive for further increased system resolution from 1/2 up to 1/64 micro steps. It also features high angular resolution in static and dynamic modes. For higher torque or acceleration requirements, the drive incorporates a boost mode as well as a power stage designed for high dynamic, peak duty performance. Combined, the EDM-453 microprocessing drive creates smoother motion with lower noise and includes a stand-by mode for heat and energy optimization.

To suit various application requirements, the mini-stepper motor is available in 5 or 12 Volt windings and unipolar or bipolar polar construction. The 42L048D can also be customized with a wide range of options. Custom shafts, magnets and coils can be fitted dependent on application requirements, as well as modification to bearings or the addition of clutch magnets and dampers. Mechanical integration by Portescap is also achievable, as well as combinations with pinions and gears.

To ensure control accuracy and reliability in a low-cost mini motor package, Portescap’s 42L048D has proved to be a well-suited partner for the vital medical assistance provided by this effective model of automated medication dispenser.