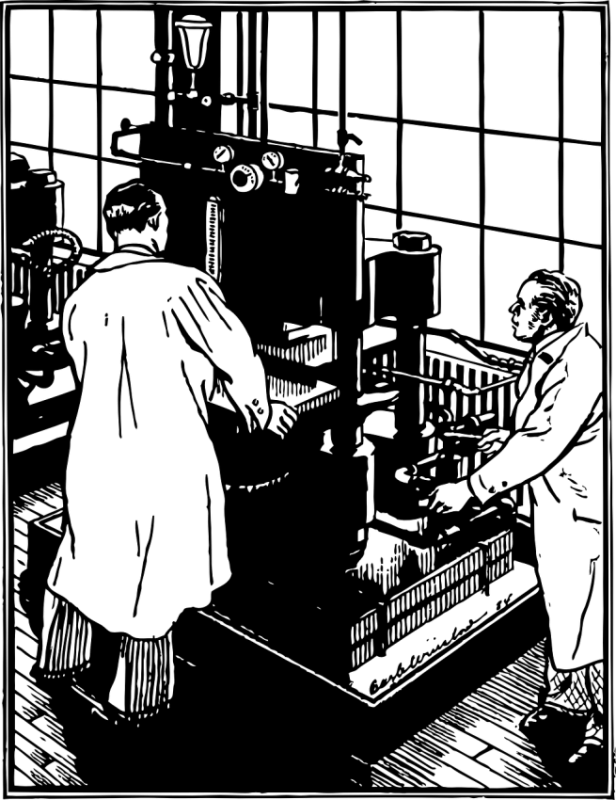

Metal casting services online, particularly aluminum die casting, play a vital role in the manufacturing of medical devices. This process involves injecting molten aluminum into a steel mold to create complex and precise components. In the medical industry, where safety and sterility are paramount, die casting offers several advantages, ensuring the production of high-quality medical devices. This article explores the importance of metal casting services online, with a focus on aluminum die casting, in ensuring safety and sterility in medical device manufacturing.

Precision and Complexity

Aluminum die casting enables the production of intricate and precise components required for medical devices. The process allows for the creation of complex geometries with tight tolerances, ensuring the accurate manufacturing of intricate parts. This level of precision is essential for medical devices that often incorporate delicate mechanisms, such as implantable devices or surgical instruments. The high repeatability of die casting ensures that each component maintains its dimensions and functional requirements consistently, meeting the stringent quality standards of the medical industry.

Material Properties and Biocompatibility

Aluminum alloys used in die casting possess excellent material properties, making them suitable for medical device manufacturing. These alloys offer high strength-to-weight ratios, corrosion resistance, and excellent thermal conductivity. Aluminum is also non-toxic, lightweight, and exhibits good biocompatibility, making it ideal for medical applications. The ability to achieve complex shapes with aluminum die casting enhances the design flexibility of medical devices while maintaining the necessary structural integrity.

Safety and Sterility Assurance

In the medical industry, safety and sterility are of utmost importance. Aluminum die casting ensures these critical aspects throughout the manufacturing process. The closed and controlled environment of the die-casting process minimizes the risk of contamination, maintaining the sterility of the components. The steel molds used in die casting are durable and can withstand high temperatures, allowing for effective sterilization methods such as autoclaving.

Moreover, aluminum die casting offers a superior surface finish, reducing the potential for bacterial growth. The smooth, pore-free surfaces can be easily cleaned and sterilized, ensuring the absence of contaminants. Additionally, die casting eliminates the need for secondary machining operations, reducing the risk of introducing foreign particles during the manufacturing process.

Cost-effectiveness and Efficiency

Aluminum die casting provides cost-effective and efficient solutions for medical device manufacturing. The high-speed production capabilities of die casting allow for large-scale production, meeting the demands of the medical industry. The process eliminates the need for multiple manufacturing steps and reduces waste, resulting in improved cost-efficiency. When this process is combined with the adoption of an MRP software, it can increase productivity to a significant percentage. Furthermore, the long lifespan of steel molds used in die casting provides a significant return on investment over time.

Quality Control and Regulatory Compliance

Ensuring quality control and regulatory compliance is crucial in the medical device industry. Aluminum die casting facilitates tight process controls, allowing for the consistent production of high-quality components. Advanced monitoring techniques, such as real-time process monitoring and statistical process control, help identify and rectify any deviations, ensuring adherence to the strict quality standards required for medical devices.

Conclusion

Aluminum die casting, as part of metal casting services, plays a crucial role in ensuring safety and sterility in the manufacturing of medical devices. With its precision, material properties, and ability to maintain sterility, die casting provides cost-effective and efficient solutions while meeting stringent quality standards in the medical industry