Element Materials Technology (Element), a leading global Testing, Inspection and Certification (TIC) company, has concluded a 10-month investigation into the metal additive manufacturing (3D printing) of patient-specific spinal implants. The work has been undertaken as part of the IMPULSO Project, with results indicating a bright future for patient safety and greater innovation between the aerospace and medical sectors.

The IMPULSO Project is an initiative funded by the Spanish Government’s Ministry of Industry, Trade and Tourism, alongside the European Union (EU), to stimulate collaboration and technological development amongst Innovative Business Clusters (AEI). As part of the Andalucia Aerospace Cluster (1), Element contributed to the discovery of how metal 3D printing, a well-established method in the aerospace sector, could be applied to the medical world to increase access to bespoke implants for patients and implant turnaround times for practitioners.

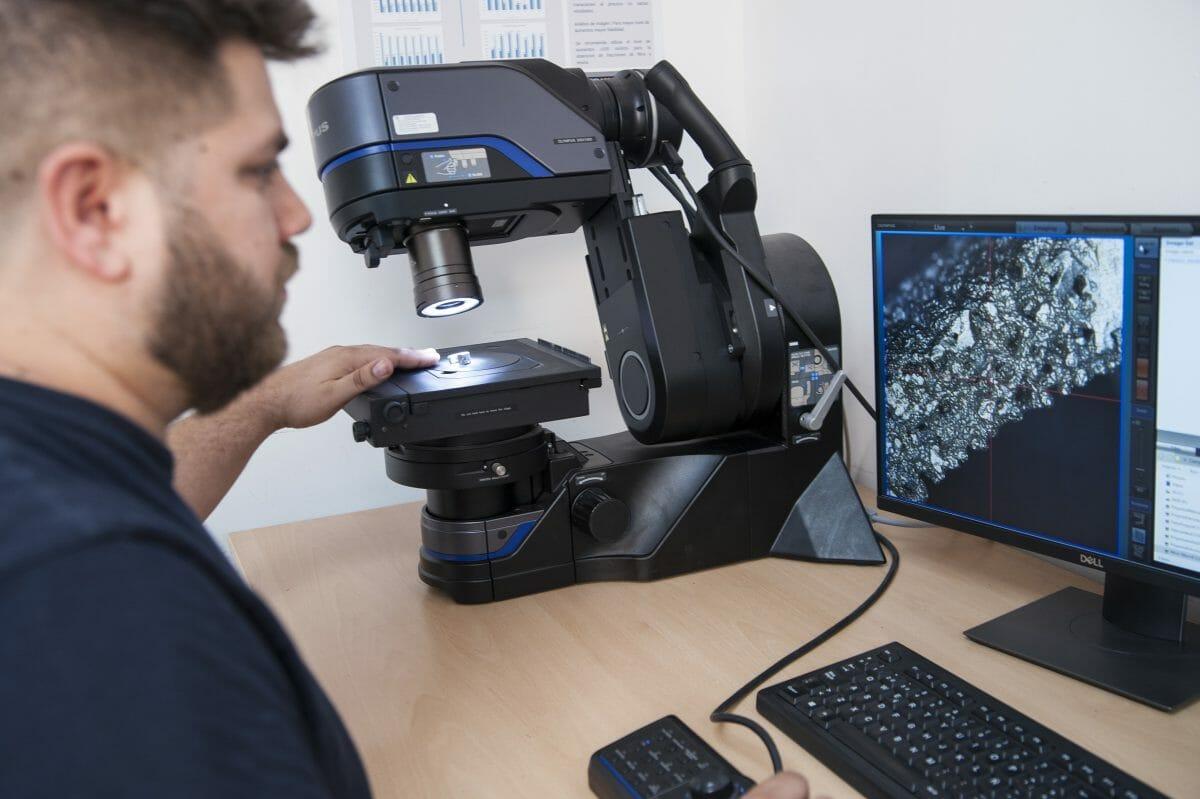

The consortium sought to create a simple and efficient methodology for implants to be incorporated into production and manufacturing. To achieve this, Element’s experts undertook a rigorous technical study to measure the implant prototypes against existing tests needed for medical device certification. This included mechanical properties testing, manufacturing process quality control and an assessment of different bio-active coatings and trabecular structures, both of which, in this case, accelerate the osseointegration process and stimulate geometry of the spine’s inner structure.

Element Seville initially worked with doctors at the Hospital Clínico Universitario de Valladolid to understand what type of implant was most needed and would benefit from the highly detailed capabilities of 3D printing. A grade 5 titanium lumbar implant (Ti6Al4v) was the result, featuring a lattice design and porous structure to create a product with exceptional mechanical properties and better biocompatibility with the human body.

By evaluating key parameters such as the adherence strength and thickness repeatability for bio-active coatings, or cavity size distribution of trabecular structures, Element can now recommend manufacturing techniques that will contribute to a better quality of life for patients, decreasing recovery times and improving implant durability.

Miguel Ángel Jiménez, R&D Manager at Element Seville, said: “We are proud to have been a part of this project which will improve the quality of life for patients in the future and make tomorrow safer than today.

“It has demonstrated how different sectors and areas of expertise can learn from each other and reinforces that knowledge sharing is key to innovation. In particular, we found great value in collaborating with our colleagues at Element Cincinnati and in our Digital Engineering business unit to harness complementary capabilities.”

Mélanie Durth, R&D Manager at Andalucía Aerospace Cluster, added: “This project, developed between several Andalucian companies within the Cluster, allows us to evaluate the aerospace technologies available in the region and to further adapt them for other specialist industrial sectors. Moreover, it is a real opportunity for our associated companies to work together and create new synergies between bellwether companies and SMEs.”