Laird Thermal Systems has developed the new OptoTEC™ MSX Series of micro multistage thermoelectric coolers and the capability to integrate them into various optical packages, including widely used TO-39, TO-46, or TO-8, creating advanced Optical Thermoelectric Assemblies (TEAs). The MSX Series utilizes advanced ceramic materials, proprietary solder bonding techniques and next-generation thermoelectric materials to boost cooling capacity by as much as 10% – all in a micro footprint. The Optical TEAs are designed for high-performance image sensing applications commonly used in analytical, industrial, and aerospace applications.

Thermal noise reduces image resolution as temperature increases. For high-end image sensing devices like IR detectors, X-ray detectors, CCD and CMOS sensors, deep cooling below ambient is required for the imaging sensor to capture maximum light spectrum.

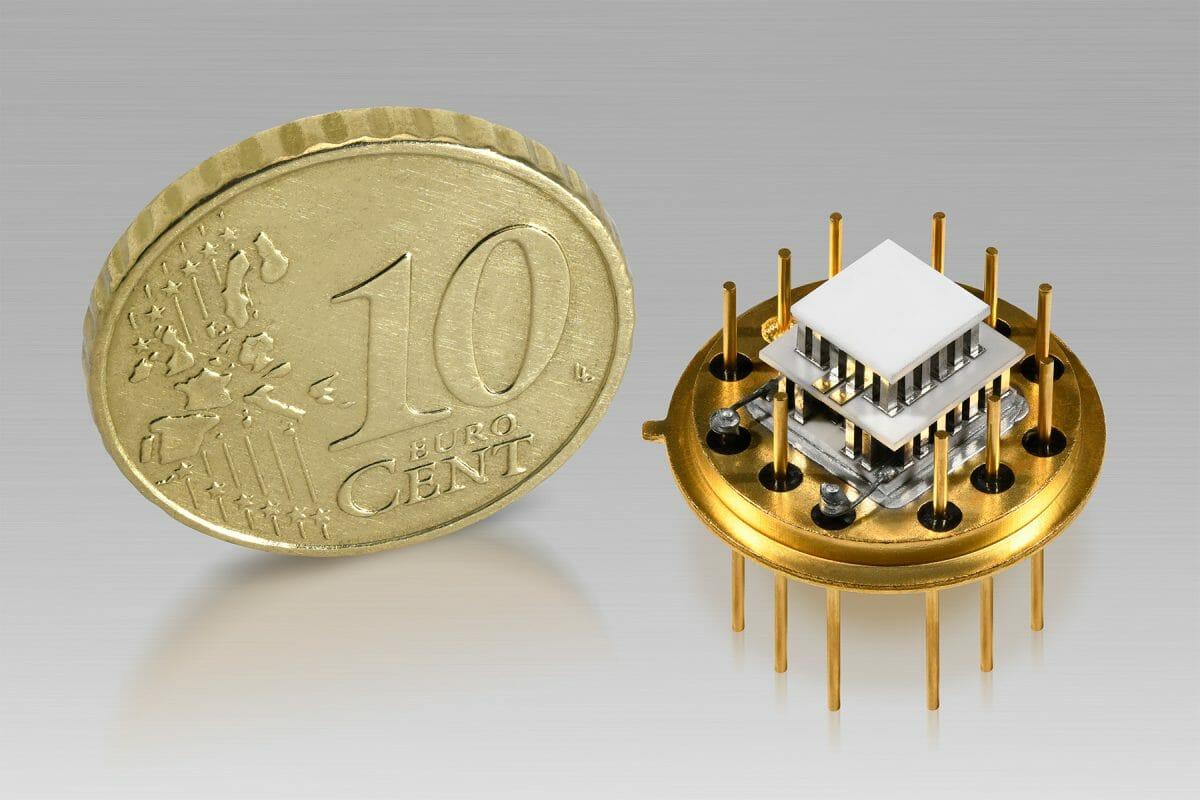

The multistage MSX Series TECs offer micro footprints on the cold side down to 2.0 x 4.0 mm with thicknesses down to 3.3 mm for 2-stage, 3.8 mm for 3-stage and 4.9 mm for 4-stage coolers.

The packing fraction for thermoelectric elements enables a high heat pumping capacity up to 5 Watts, with lower operating currents than traditional multistage coolers. Featuring solid-state construction for long life reliability and no maintenance, the micro multistage thermoelectric coolers deliver reliable temperature stabilization from room temperature down to 180 Kelvin with no outgassing.

Manufactured in the USA, Laird Thermal Systems has invested in advanced automation equipment to integrate the multistage coolers into miniature optical packages in-house. This saves customers the burdensome task of integrating TECs into their packages, reducing assembly time and costs and improving repeatability.

“Advanced process automation has enabled a new level of miniaturization for our MSX multistage series to support next-generation imaging solutions that require smaller optical packages,” said Andrew Dereka, Thermoelectrics Product Director at Laird Thermal Systems. “Developing proprietary Optical TEA capabilities with minimal solder voiding ensures that our customers receive Optical TEAs with the highest quality, without the hassle of building assemblies themselves.”

The MSX Series is undergoing Telcordia GR-468 CORE qualification to ensure high repeatability and long-life operation in optical environments. More here.