Phillips-Medisize, a Molex company, and a leader in the design, engineering and manufacturing of pharmaceutical drug delivery, invitro diagnostic and medtech devices, has teamed with GlucoModicum, an innovative medtech company based in Finland, to design and eventually commercialize a proprietary non-invasive, wearable device that removes technology and patient-care roadblocks to continuous glucose monitoring (CGM).

“We wanted to create a solution that is needle free, accurate and more affordable so people would better monitor their glucose,” said Jokke Mäki, managing director of GlucoModicum. “Working with Phillips-Medisize, we applied compelling science to develop a world-class product that may help billions of people better manage their diabetes.”

Accelerating the Product Innovation Journey

In seeking a more convenient, rapid and gentle CGM alternative, GlucoModicum discovered that magnetohydrodynamic (MHD) technology could be used to apply a small amount of energy directly to interstitial fluid—the body fluid between blood vessels and cells—to drive it to the surface of the skin for quick and easy extraction of a glucose sample.

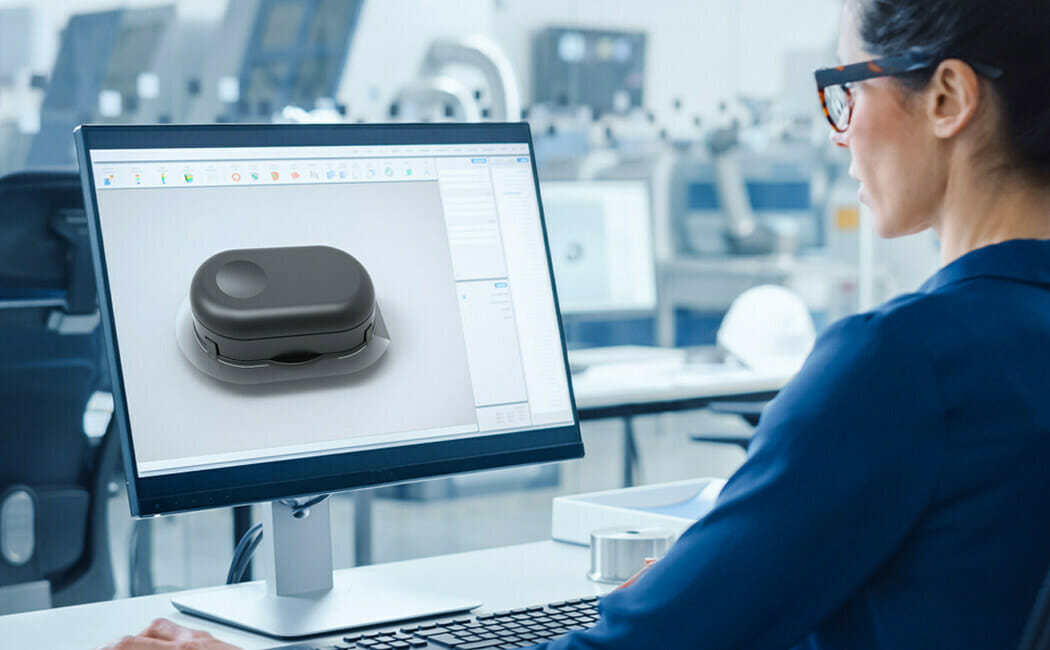

While their scientists conducted rigorous research, GlucoModicum sought an experienced contract development and manufacturing organization (CDMO) to assist in realizing their vision for a new device, called Talisman. This device is designed to adhere to a patient’s arm, and integrates the MHD technology, ultra-sensitive biosensors and advanced algorithms while connecting to a smartphone app for data collection and reporting. The device is not yet FDA approved and does not have the CE mark.

In developing the Talisman, Phillips-Medisize applied special expertise in industrial design, mechanical and electrical engineering, connectivity, material science, miniaturization, supply chain management, software development, manufacturing, testing, quality assurance and regulatory compliance.

“We started with ideas, concepts and drawings,” said Homer Fairley, business development manager for Phillips-Medisize. “The day we provided the finished sample product to GlucoModicum was a moment of celebration for both parties, as it really brought the possibilities to life. Now that there is a proven concept, we look forward to the opportunity to leverage Phillips-Medisize’s high-volume manufacturing capabilities to produce hundreds of millions of units on time and in a cost-effective manner. That’s a big benefit to this project.”

In November 2022, GlucoModicum published results of the safety, efficacy and effectiveness of its proprietary MHD technology in Scientific Reports, based on glucose tolerance tests conducted on five healthy volunteers. The results further supported previously published data that demonstrated GlucoModicum’s MHD technology and biosensor solution was 13 times more effective than other needle-free approaches tested in extracting interstitial fluid from the skin. Additional testing of the five healthy volunteers revealed that Talisman’s biosensor is eight times more sensitive to glucose molecules than comparative biosensors on the market.

Since a CGM informs treatment decisions, the clinical efficacy and documentation required by notified bodies and similar regulators, such as Food and Drug Administration (FDA) and Pharmaceutical and Medical Device Agency (PMDA), are critical to planning a successful launch. The Phillips-Medisize Design and Development team offers its medical customers regulatory capabilities customized to each company’s needs—from regulatory documentation to guidance on device classification, risk assessments and device-specific submission requirements for regulatory bodies. In this case, Phillips-Medisize counseled GlucoModicum on what will be required for submissions to regulatory bodies in the markets where the company plans to launch this device. The GlucoModicum team found the advice and regulatory knowledge insightful and beneficial to their commercial launch plans.

Preparations are underway to leverage Phillips-Medisize’s global manufacturing footprint, extensive supply chain network and advanced assembly automation capabilities to produce hundreds of millions of devices and biosensors once in-depth clinical studies and regulatory approval are completed. Together, the companies are also beginning to explore other potential uses of this innovative technology to support management of other diseases.

Supporting Resource