From operating rooms to medical devices, reliable disinfection is essential in the fight against hospital-acquired infections, antibiotic-resistant bacteria, and viruses that are continually mutating.

In published scientific research and University studies, UV-C has proven effective in deactivating various strains of coronavirus, including the latest SARS-CoV-2 strain that causes COVID-19.

This article will cover how Solvay, a leader in UV stabilization technology, enables end users to achieve effective UV-C disinfection of polymeric surfaces without compromising on material performance.

Let’s take a step back and zoom in on UV-C light itself. UV-C refers to high-energy short-wavelength (200 – 280 nm) ultraviolet light, which is normally filtered by the earth’s atmosphere and is much stronger than UV-A and UV-B energy found naturally in sunlight. The high-energy UV-C light is absorbed by the genetic material of microorganisms, resulting in molecular damage, causing them to cease to function or reproduce, and eventually become harmless. While the most typically used UV-C wavelengths are in the range of 250 nm to 270 nm, the entire 200-280 nm UV-C bandwidth has generally been recognized for its germicidal effects. The level of UV-C exposure required for effective treatment varies from pathogen to pathogen. UV-C technology can be applied for high contact surface disinfection or for upper air disinfection as well.

In practice, the effectiveness of UV-C light depends on factors such as:

- exposure time

- distance between the UV-C lamp and the surface

- ability of the UV-C light to reach the viruses in water and air

- folds and crevices in materials and on surfaces

- peak energy output and its wavelength

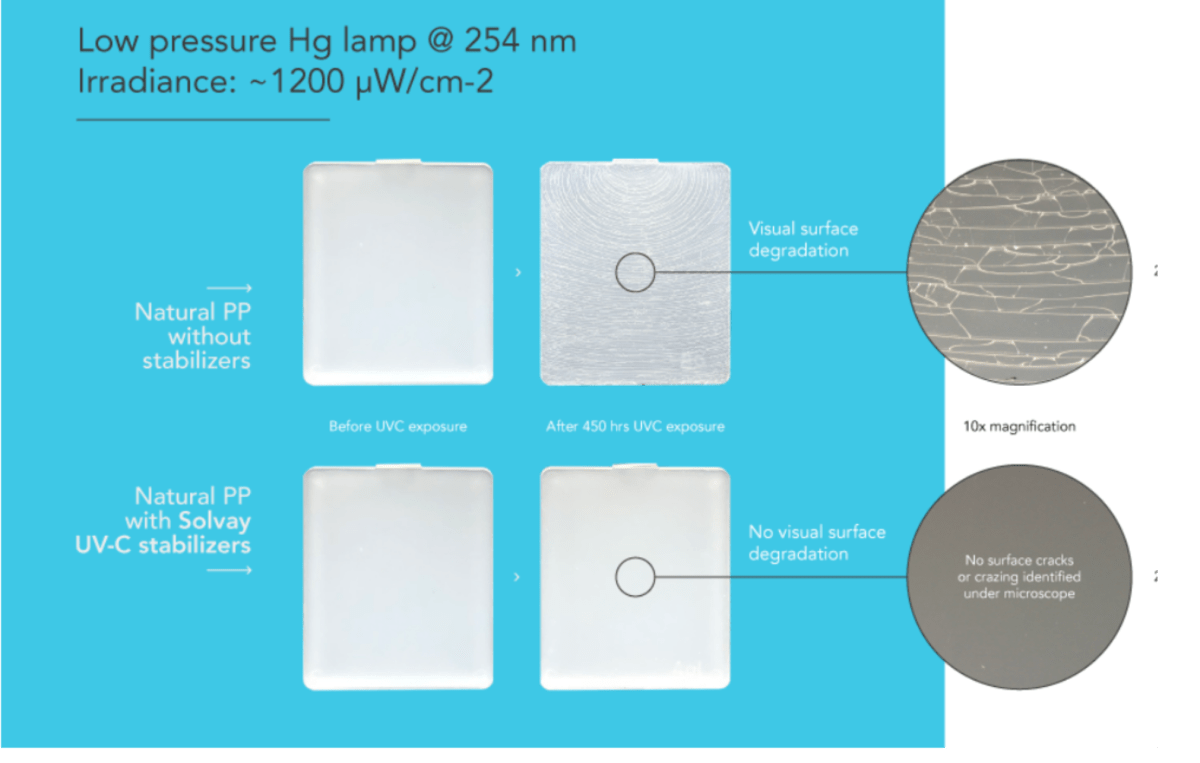

The closer the UV-C lamp is to the material surface, the higher the level of radiation the surface will need to endure to maintain stability. Due to its activity, UV-C light should always be used according to precise safety specifications. Typically, the higher energy level of UV-C irradiation will cause materials to degrade much faster than with UV-A or UV-B exposure. In some cases, the first signs of material degradation can be seen in just a matter of days. Today, plastic articles and surfaces are not typically formulated with long-term UV-C exposure in mind and can start to discolor and crack when exposed to UV-C irradiation. Current UV stabilizer systems are designed to stabilize polymers against UV-A and UV-B irradiation (280 to 400 nm) but not UV-C irradiation. Our research indicates polymers have different degradation behaviors after UV-C exposure as there are indications that the degradation pathway may not be the same as the degradation pathway after UV-A and UV-B exposure. Specific knowledge and expertise in UV-C stabilization is required in order to sufficiently protect a polymer system from degradation. By incorporating Solvay’s UV-C stabilizer into the polymeric materials, protection against UV-C damage can be achieved. Traditional mainstream UV-A and UV-B stabilizers have been shown to be ineffective in stabilizing high-energy UV-C irradiation.

Recognizing the importance of UV-C stabilization for the plastics industry and public health and safety, Solvay, a member of the International Ultraviolet Association (IUVA, www.iuva.org) is currently leading the IUVA Materials task force which includes experts from various industries such as UVC lamp manufacturers, UVC device manufacturers, medical device manufacturers, and aerospace. The objective of the task force is to investigate the effects of UV-C light energy on various polymeric materials. The results from this comprehensive in-depth study will be published in the second half of 2022.

Solvay’s proprietary UV-C stabilization technology enables UV-C light to be used as an antimicrobial disinfectant to guarantee a healthy environment while assuring the long-term durability of polymeric parts and devices. Solvay’s UV-C stabilization technology enables UV-C disinfection to serve as an environmentally friendly procedure that helps eliminate the need for single-use plastic waste. By reducing the need for chemical wipes and plastic dispenser bottles containing alcohol gels, UV-C disinfection can improve sustainability while helping to address today’s public health challenges.

You can find out more on the Solvay website or by visiting Solvay at the k 2022 in Düsseldorf, from October 19-16 in Hall 6, Booth C61.

Editor’s Note:

Sophie Poelmans is the Global Marketing Manager at Solvay with more than 20 years of experience in the polymer industry.

Andrea Landuzzi is the Global Marketing Director at Solvay with more than 25 years of experience in the polymer industry.

Jerry Eng is the Global New Business Development & Technical Service Director at Solvay with more than 30 years of experience in the polymer industry.